“Integrity points” – a new approach for generating reference points

Reference points are an important pillar of localisation systems. Such points are well defined, and their “true” location is known very accurately. In current train localisation systems, such reference points are typically fixed on the track (e.g. Eurobalises or track clear detection units). Because of their proven reliability and ease of installation, such reference points are used within train protection and train management systems. But a major drawback of these points are the high installation and maintenance costs (CAPEX and OPEX).

One way to reduce these costs is to lower the number of reference points needed. This implies an improvement of the localisation system in terms of increasing both the reliability and the accuracy of the dead reckoning between the different reference points.

Another approach is to lower the average cost of a reference point. As mentioned above, reference points, which are fix installed within the track infrastructure, are expensive. Therefore, an alternative could be to use reference points which do not rely on such fix installed elements, but still fulfil all requirements in terms of accuracy, reliability and safety.

Such an approach is currently under investigation within the SBB AG. The method is based on matching train borne sensor measurements with accurate and reliable topological and topographical information from a database (a digital map). The obtained points are called integrity points. Currently they are used to validate routing information but can form a basis for reference point generation in the future.

At the beginning of creating an integrity point, the train calculates its travelled distance from the last known integrity point, similar to current train odometry systems. In a next step, the distance is transformed into a position on the map and all available sensor measurements are compared with topographical information of the proposed point. If all compared elements stay within a maximal boundary, the estimated position is regarded as a new integrity point, to which the next distance measurement can be related.

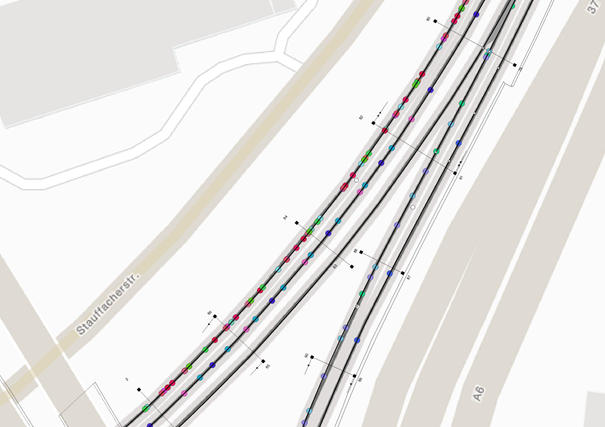

As the integrity points do not depend on fix installed infrastructure elements, the position of these points can differ between several train runs, see Figure 1. Each point represents an integrity point and each colour shows a different train run. It can be seen that not only the position of the points differs between the train runs, but also their density. This might be due to different speed profiles of the train runs and will be investigated in future work.

More details of the proposed method can be found in the publication “Integrity Measures and Verification for Train Localisation” on the smartrail webpage or direct via this link. Future work will focus on optimising the proposed method and integrating additional sensor measurements to get closer to reference point generation which fulfils safety requirements.

Marco Moos, CLUG project manager for SBB